WIRELESS ADDRESSABLE LPG Detector

FUNCTION

- LPG Detector can detect the gas leaked in time, and send out sound flash alarm signal correctly. Applicable to the gas existing sites, such as house hotels, flats etc. independent & network alarm output optional.

INSTALLATION

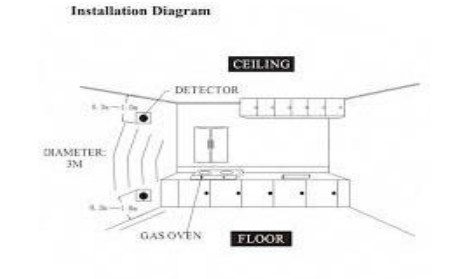

- Please confirm the test gas is heavier or lighter than air. The gas heavier than air: LPG etc. The gas lighter than air: natural gas, marsh gas etc.

- Choose the suitable position to install the detector according to the gas heavier or lighter than air. detecting the gas heavier than air: installation height above floor:0.3-1.0msemi diameter to gas source:<1.5m; Detecting the gas lighter than air: installation height below ceiling:0.3-1.0m semi-diameter to gas source:<1.5m.

- For Family installation, please note that do not install the detector near to cooker, oily fume site, otherwise it will lead to false alarm or gas inlet blocking, and influence the sensitivity. Also avoid installing the detector close to the following sources of interference: direct air flow from vents, fans, doors, windows, sources of steam, etc.

USAGE

- INDEPENDENTLY

- Choose a suitable position to installed the detector according to the installation

- NETWORK

- Choose a suitable position to installed the detector according to the installation. Connect with N.O or N.C according to the control system.

- DC 12V or AC 220V Power supply is the factory setting, connect the power supply accordingly. Orange, Red, and Green LED flashes alternately for 1 minute, it means the inner sensor is activated, self -test finished. Detector gets into normal state.

TESTING

- Simulation Test

- Press the test/reset button, while the buzzer sends out a DEEP sound, loosen the button immediately. Detector comes to analogue alarm mode to test all the function. Detector resumes to normal working state after 15 seconds

- Real Test

- To test the installed detector while using independently or in network, you can give some gas around at a distance of 5cm to the gas convection windows by using a gas lighter in non-ignition condition. Frequent tests may result in reducing the sensitivity of the detector. The gas alarm density is set according with the criteria of GB15322-2003.the detector will stop alarm and resume the detecting state while the gas density reduced.

NORMAL MAINTENANCE:

- Prolonged use of the Detector, the gas convection window will have some oil adhesion, and influence the sensitivity. We suggest the user to clean the detachable gas convection window every three months, please retest the detector after cleaning.

EMERGANCE ALARM TREATMENT:

The detector alarms while the gas density in air reach or beyond the alarm density level. The relative treatments as below:

- Shut off the tube valve immediately.

- Open the Window to make the air flow rapidly.

- Extinguish all fire sources and anything can make fire e.g. Lighter, matches etc.

- Avoid open/close all kinds of electricity.

- Cheak the reason of gas leaking, and inform the relative department and professional persons in time.

LED INFORMATION:

- Red LED Flash ---------------------------------------> gas leaking

- Orange LED ON -------------------------------------> inner malfunction

- Red, Yellow, Green LED Flash alternately ----> sensor warm up and self-test

- Green LED ON --------------------------------------> normally working