MACHINERY CONTROL CABINET PROTECTION WITH FLAME TRACE - AUTOMATIC EXTINGUISHING SYSTEM

APPLICATION OVERVIEW - PROTECTING ELECTRICAL CABINETS WITH FIREFINDER

- Machinery Control Cabinets - maintain and control vital processes within an organization. The loss of or damage to an electrical cabinet by fire can cause catastrophic impairment to an organizations’ ability to continue a critical operational procedure. This can lead to financial loss, downtime or loss of ability to function.

A BURNT OUT MACHINERY CONTROL CABINET

- Worst Case Scenario: This is a photo of a burnt out MCC which did not have any automatic in cabinet fire protection. For any industry, the loss of time required to restore the system and normalise the production or system restoration cannot be recovered. However a financial loss may not cost dearly. In this case, the smoke alarm was triggered but by the time fire brigade could extinguish the fire, the damage was done.

- A small fire starting in a low cost electrical cabinet can spread and cause millions of Rupees worth of incremental damage. A Fire of this nature can impact the whole operation of a business and cause serious life safety issues. Small Fires can lead to huge damage and cost. Protecting Electrical cabinets with a low cost but highly effective Firefinder Protection System can be part of responsible Fire Risk Reduction program inside an organisation.

Solutions

- The common systems selected to protect electrical cabinets are Firefinder FE36 or Novec- 1230 Direct Low Pressure Systems. The extinguishing agent is electrically non-conductive and can be delivered directly onto the source of the fire in a charged or live cabinet extinguishing at the point of ignition immediately. The discharge of agent will continue through the burst point in the Firefinder Detection Tube until the Firefinder cylinder is empty. This means that the entire cabinet becomes filled with extinguishing agent at a design concentration which prevents fire spread and fire or re-ignition. As a general guide we would suggest 1KG (2.5lbs) of extinguishing agent per cubic metre of internal cabinet volume. This is well above the heptane cup burner extinguishing concentration values of each extinguishing agent but far under the LOAEL of the room volume meaning the extinguishing power of a Firefinder system in electrical cabinets is exceptionally high whilst completely safe for use in occupied spaces.

INSTALLATION

- Firefinder systems are modular, self-contained detection and extinguishing systems.They do not require an external power supply to operate and their installation is very simple. Whilst other Fire extinguishing systems require installation of pipe work, pressure ventilation outlets, and a dedicated area for cylinder storage Firefinder Cabinet protection systems are installed in, on or close to the Fire Hazard itself.

INSTALLING FIREFINDER

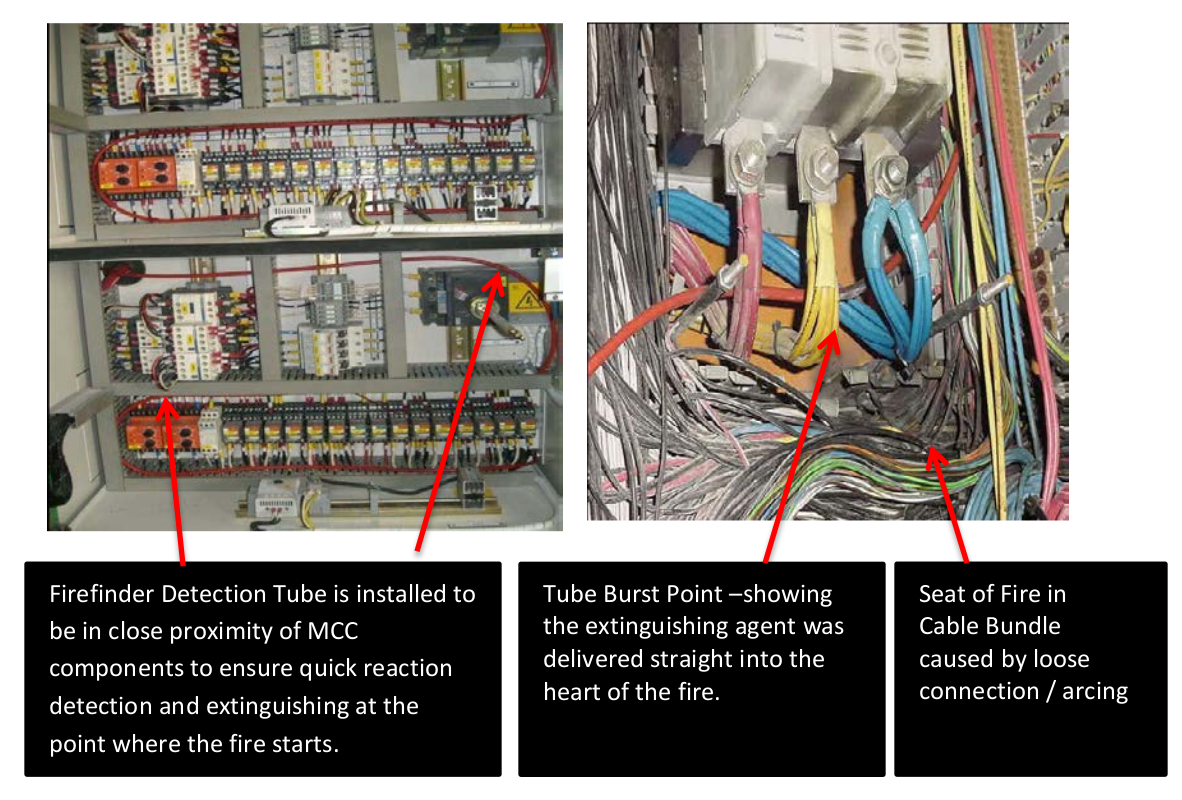

- Fires in electrical cabinets are normally rapid developing fires caused by short

circuits or arcing meaning there is typically a very short time between fire

development and physical flame. The use of the Firefinder Detection Tube

strategically located in close proximity to the individual components will rapidly

detect and then extinguish a fire as shown in the photographs. Unlike systems

that require discharge through nozzles or diffusers – the strength of the

Firefinder solution is that the agent is always delivered straight to the heart of

the fire - wherever it starts - leading to instant extinguishing. There is no time

wasted, taken to fill an enclosure to an extinguishing concentration.

The fire is rapidly extinguished and the damaged components can then be easily and quickly replaced. The Firefinder system prevents fire spread within the cabinet meaning that a fire is quickly contained and limited to the place where is starts.

Firefinder systems can be supplied with a Pressure Switch and can be integrated into the Fire Alarm system immediately notifying on site engineers that a fire has been detected and extinguished.

FIRE ALARM INTEGRATION

- The Firefinder system can be delivered with normally open /normally closed Low Pressure Switch. This allows the discharge of a Firefinder system to be monitored and integrated with the Fire Alarm or Building Management system. This output signal can perform other functions as required ie sounding alarms, shutting down equipment, activating dampers, fire doors etc. The Firefinder systems do not need to be connected to an external power supply source so even in the event of a general power failure the Firefinder System is always ON and ready to protect critical equipment against the risk of fire.

So Why is Firefinder so Good for Protecting Electrical Cabinets?

- Fire Detection Tubing systems are the ideal in-cabinet Fire Protection solution and are installed in thousands of locations worldwide. They quickly detect and extinguish fires inside critical equipment. The extinguishing agent is delivered straight onto the source of the fire through the burst point in the Fire Detection Tubing, extinguishing it immediately.

- Unlike some other technologies there is no delay in the build-up of an extinguishing concentration or a delay caused because the extinguishing gas must find a way into the cabinet and to the source of the fire from the outside. Firefinder systems localise the fire and prevent fire damage to the cabinet components.

- Each electrical cabinet can be protected on an individual or grouped basis (depending on hazard analysis and risk assessment) so a fire in a given cabinet does not lead to the costly discharge of a large amount of room volume extinguishing agent meaning refill costs are low. Firefinder systems are small, refilling and reinstallation is quick.

- Above all, the benefit of Firefinder systems is in the Firefinder Detection Tubing. The Detection tubing allows detection anywhere inside the cabinet meaning the fire is detected and extinguished at an early stage – at the point where the fire starts.Other technologies using “glass sprinkler bulb” type actuators discharge much later as the heat must build up around the glass bulb and reach a certain temperature to break it. This can be a problem if the glass bulb is located a distance from the source of the fire as the fire needs to be of unacceptable size before the glass bulb breaks –meaning that the electrical cabinet might be completely destroyed before the extinguishing agent is deployed.

- Systems that discharge through pipework and nozzles have the difficulty in delivering the extinguishing agent rapidly onto the fire source. Electrical Cabinet manufacturers are hesitant about maintaining warranty and type test certificates on Electrical /Machinery Control Columns that might be installed with electrically conductive (metal) pipework.

- The Firefinder Detection Tubing is electrically non-conductive and is flexible enough to be routed through the electrical cabinet just like any other “cable”.

- It is the simplicity, efficiency and effectiveness of Firefinder Direct Low Pressure Detection and Extinguishing systems that makes them appear purpose built for protecting critical Electrical and Machinery Control Cabinets from Fire. By choosing

YOU ARE NOT JUST PROTECTING YOUR ELECTRICAL CABINETS BUT

ALSO

- BUSINESS OPERATION, MANUFACTURING, PROCESSES, QUALITY CONTROL, CAPABILITY, REVENUES, PEOPLE, CONTINUITY,CUSTOMER CONTRACTS,CONTROL, ABILITY TO FUNCTION

WILL KEEP YOU SAFE FROM FIRE